Tiny robots made of metal and plastic

Researchers at ETH Zurich have developed a method that allows them to create micrometer-sized machines in which several materials are interwoven in complex ways. Such microrobots are expected to revolutionize medicine one day.

Robots so tiny that they can move through our blood vessels and deliver drugs to specific locations in the body - this is a research goal that scientists have been pursuing for years. Researchers at ETH Zurich have now succeeded for the first time in building such "micromachines", which consist of metal and plastic, and in which these two materials are linked together in the same way as, for example, the links in a chain. This is possible thanks to a new manufacturing technique they have developed. "Metals and polymers have different properties, and both materials offer advantages in building micromachines. To take advantage of all these properties at the same time, we wanted to combine the two materials," explains Carlos Alcântara, a former doctoral student in Salvador Pané's group at the Institute of Robotics and Intelligent Systems and one of the two first authors of the paper. Usually, micromachines are driven from outside the body with magnetic fields. To do this, magnetic metal parts must be built into the micromachines. Polymers, on the other hand, have the advantage that they can be used to construct soft and movable parts or those that dissolve inside the body. If drugs are embedded in such dissolvable polymers, targeted active ingredients can be released at specific points in the body.

High-tech manufacturing method

The new manufacturing method is based on the expertise of ETH professor Salvador Pané. He has been working for years with a high-precision 3D printing technique that can produce complex objects on a micrometer scale: 3D lithography. The ETH scientists have used this technique to produce a type of casting mold for their micromachines. The latter have thin channels that serve as negatives and are filled with the appropriate material.

Using electrochemical deposition, the engineers fill some channels with metal, others fill them with polymers. Finally, the mold is dissolved with solvents. "We were able to develop this method because electrical engineers, mechanical engineers, chemists and materials scientists work closely together in our interdisciplinary group," says Fabian Landers. He is a doctoral student in Pané's group and also first author of the paper, which was published in the journal Nature Communications.

Vehicle with magnetic wheels

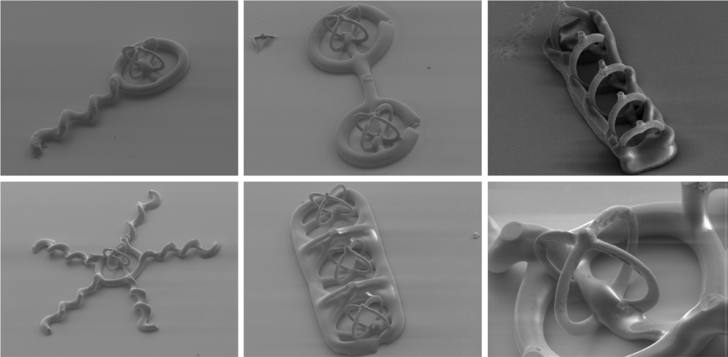

As a proof-of-concept of interwoven micromachines, the ETH engineers made several tiny vehicles with plastic chassis and magnetic metal wheels that can be driven by a rotating magnetic field. Among them are ones that can move on a glass surface and others that can float in liquid or on a liquid surface, depending on the polymer used.

The scientists will now continue to develop their two-component micromachines and experiment with other materials. They will also try to make more complex shapes and machines, including ones that can fold and unfold. In addition to drug-delivering ferries, future applications include micromachines that can treat aneurysms (bulges in blood vessels) or perform other surgeries. Another research goal is unfoldable stents (tubular vessel supports) that can be delivered to the desired location in the body using magnetic fields.

Original publication: Nature Communications – Mechanically interlocked 3D multi-material micromachines

Image source: Nature Communications – Mechanically interlocked 3D multi-material micromachines

Source: ETH Zürich – Winzige Roboter aus Metall und Kunststoff